“You are my manual handling saviour!!!”

Posted by Kelly Hall on 3rd Oct 2025

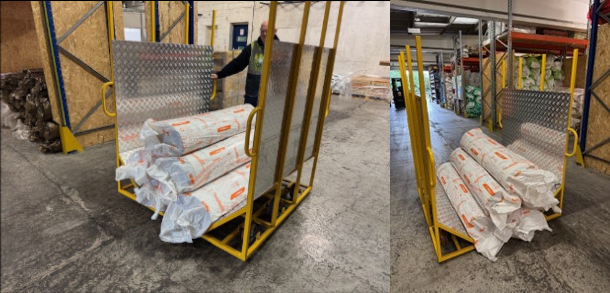

From design to delivery Handle-iT created a bespoke dolly for moving flooring reels for BL Flooring in Bristol. When it comes to handling awkward materials like flooring, off-the-shelf equipment often falls short. That’s why one of our recent projects involved designing and fabricating a custom dolly, engineered specifically for a customer who needed a safe and efficient solution to move large reels of flooring.

From concept sketches to stress testing, assembly, and final delivery, here’s how we turned a complex requirement into a practical tool.

Understanding the Challenge

Flooring reels are bulky, heavy, and not always easy to manoeuvre. Standard trolleys can’t cope with their dimensions, nor do they provide the right support to prevent reels from rolling or shifting during transport. Our customer needed a solution that would:

- Support the weight of heavy flooring reels.

- Provide stability and balance during movement.

- Be durable enough for daily use in a warehouse environment.

- Remain easy to operate for a single person.

- Access from both sides for ease of loading.

- Speed up delivery process and to make it safer.

This meant that Handle-iT was needed for bespoke design and manufacture.

The Design Phase

We started by sketching out concepts, working closely with the customer to understand reel sizes, weight ranges, and handling conditions. Anyone can design something with big and heavy materials but this would render it unusable in practice.

The final design featured:

- A sturdy aluminium chequered plate base, chosen for its balance of strength, lightweight properties, anti-corrosion and slip resistance.

- Precision-welded framing of 30 x 3 box section to provide rigidity without unnecessary bulk.

- Aluminium Centre Castors with Bonded PU Tyres, capable of supporting high loads while allowing smooth movement. Wheels are recessed into the frame cavity to stop trip hazards or to avoid hitting the wheel and bending the solid 20mm axle

- A cradle design that securely holds reels in place while in motion and helps to distribute the load.

- The cavity in the base puts weight where we want it to be, not where the roll wants to go which would be to the side.

“Drawing looks spot on guys”

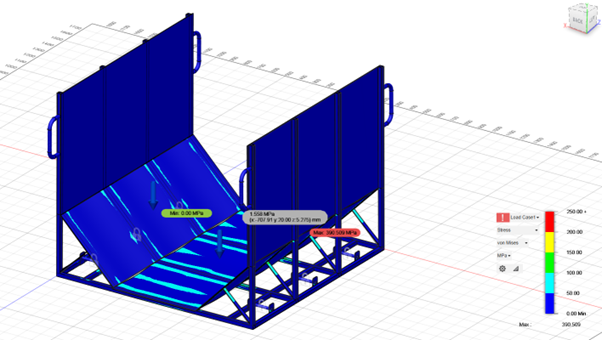

Stress Testing

Safety and reliability were critical. Ahead of fabrication, we put it through a rigorous series of stress tests based on materials used and design:

- Load capacity tests to ensure the dolly could handle more than the maximum reel weight.

- Dynamic tests to simulate pushing, pulling, and turning with heavy loads.

- Surface tests on smooth concrete, warehouse floors, and uneven ground.

Gussets were added to deflect weight from the sides to the base which relieves the strain that the sides will take over a period of time.

These tests confirmed the dolly could withstand the demands of everyday use without risk of failure or instability.

Assembly

Every unit is assembled in-house by our experienced team, with careful attention to detail:

- Edges were finished to remove sharp corners, ensuring operator safety.

- Castors were mounted and aligned for maximum durability.

- Aluminium surfaces were checked for integrity and polished for a professional finish.

From discussion, concept, rough sketch to full CAD drawing to assembly, keeping everything in one place means that we can control quality at every stage.

Delivery to the Customer

Once completed, the dolly was delivered directly to the customer. We highlighted safe handling practices and maintenance tips to extend the dolly’s working life.

The end result? A bespoke solution that fit seamlessly into the customer’s workflow, saving time, improving safety, and reducing strain for their team.

And the Customers thoughts…

The trolley is great. Very usable for the specific purpose we got it for. Thanks for making the vision a reality! Appreciate your help as always!

Happy warehouse staff – happy me!

This bespoke dolly project is a great example of how custom engineering can solve unique material handling challenges. By working closely with our customer and taking the project from design to delivery, we were able to create a solution that not only met but exceeded their expectations.

Whether it’s flooring reels, oversized components, or other awkward loads, sometimes the right tool doesn’t exist until it’s built. That’s where bespoke fabrication makes all the difference.